Earlier this year, prior to the restrictions imposed as a result of COVID-19, we travelled to Berab in Papua as part of our Improving Cacao Farming and Unleashing Sago Potential in Papua Project. Through this initiative, we are aiming to improve the quality of cacao beans through pre-harvest and post-harvest interventions in cacao production in Papua.

Indonesia is the third largest cacao producer in the world.

Pre-Harvest Intervention: Good Agricultural Practice (GAP)

To improve the quality of cacao, we facilitated a Good Agricultural Practice (GAP) training session with the farmers. GAP, as defined by FAO, are principles to apply during on-farm production and post-production processes, in order to produce safe and healthy food and non-food agricultural products, while taking into account economic, social, and environmental sustainability.1 We used interactive modules, videos, and field practices to introduce the GAP principles and engage the farmers through participatory approaches. Ten farmers participated in the training, all of whom were very enthusiastic to learn about new ways to improve their farming methods.

Good Agriculture Practice (GAP) Training in Berab, Papua.

Post-Harvest: Re-designing and Building the Solar Dryer

Inefficient drying techniques are one of the major challenges faced by cacao farmers in Papua which often result in low quality of cacao and subsequently low market value. Our Unmet Needs research in 2018 estimated that annual economic losses of cacao are more than IDR 70 million. The study also found that most of the cacao farmers dry their commodities by laying them on the ground which lacks protection from rain, dirt, and contamination by various pests. This technique contributes to a low price of dried cacao beans.

Since 2016, Kopernik has been working on multiple designs of solar dryers for a range of commodities to support smallholder farmers in improving their post-harvest processes. Prior to designing a solar dryer, we conduct a baseline survey to assess various aspects such as current farmers’ production capacity, land condition, available space, sun exposure as well as the local availability of construction materials. These considerations are important inputs for the design and construction of the solar dryer.

Together with cacao farmers in Berab, Papua, we built a solar dryer to improve their past-harvest process.

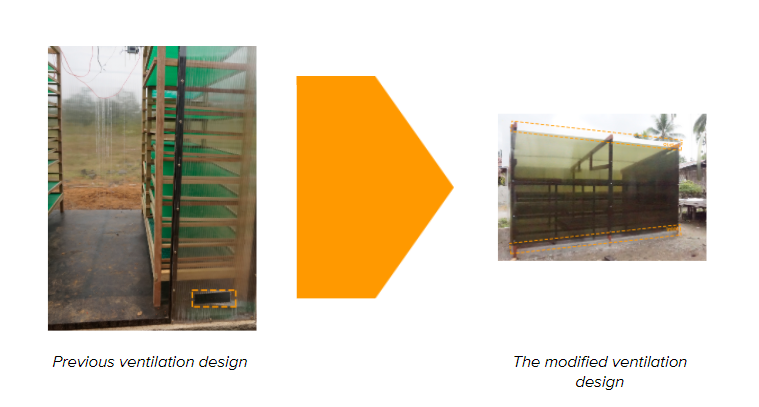

From the process of designing and building our previous solar dryers, we knew that sufficient air circulation is essential to enable the commodities to be evenly dried inside the solar dryer. Therefore, we improved our solar dryer designs in Papua by adding more ventilation to allow for good air circulation and enable effective passive drying. In addition, we also added additional space in between the drying racks to ease the farmers ability to stir the beans. In our previous design, the space between the racks was only 12,5 cm, but this time, we created a 30 cm distance between the racks, so the farmers will have more room to regularly stir the beans.

Berab is a remote village far from the city center in Papua with limited resources, so when building the solar dryer, we tried to use locally available materials. With local materials, the procurement process was easier and would hopefully encourage other communities in Papua to replicate the technology. One of the key materials used for the roof and the walls of the solar dryer is polycarbonate, which enables the capture of a high level of light transmission and is easy to work with. However, if polycarbonate is not available, we can also use Polypropylene Roofing or UV plastic as an alternative.

For the frame structure, we usually use iron and have done so in our previous designs, however, in Papua, we used wood because people are more familiar working with wood, and the price is much cheaper.

The farmers were excited to complete the solar dryer construction, even though we faced many challenges including a limited supply of electricity and limited materials. The farmers carefully followed the guidelines provided and were able to finish the construction within five days.

Once completed, the farmers were eager to use the solar dryer straight away to test how it could improve their post-harvest productivity. According to the farmers, the solar dryer reduced the drying time from five to three days. We will continue to collect data and performance as well as other benefits of the solar dryer. Stay tuned for more updates on our solar dryer initiative Papua!

1A Scheme and Training Manual on Good Agricultural Practices (GAP) for Fruits and Vegetables, Volume 1 The scheme - standard and implementation infrastructure, 2016, FAO. http://www.fao.org/3/a-i6677e.pdf